Affordable Dry Sorbent Milling Technology

An Entire State-of-the-art Sorbent Milling System

for ABOUT THE COST OF A MILL ALONE

Available Configurations

• Simple Unenclosed Mills

- Pin Mills

- Hammer Mills

- Screen Mills

- Fluidized Jet Mills

• Fully-enclosed Smart Mills with Dosers

- Bicarmill

- Compact

Design Benefits

• Low power consumption

• Guaranteed particle size

• Low vibrations

• Low sound emissions

Industries

• Steel • Non-ferrous Metals Primary Process • Cement •

• Incineration • Boilers • Biomass • Waste-to-Energy •

Advanced Dry Milling and Grinding Solutions That Work

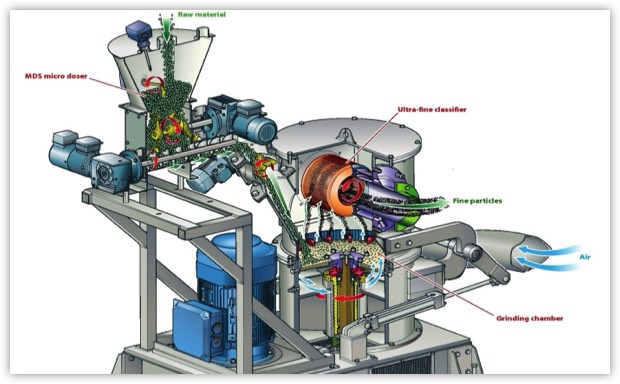

JCF Hammermill System Schematic

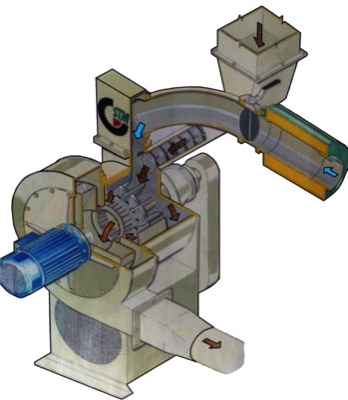

Bicarmill - The Original Bicarbonate Smart Mill

Founded in 1980, STM develops advanced technologies in the field of fine and ultra-fine milling, with over 30 years experience in fine milling of sodium sorbents for the purpose of cleaning flue gases.

STM was instrumental in developing dry sodium bicarbonate scrubbing technology as it supplied the first milling systems to Solvay Minerals for the application of sodium sorbent acid gas scrubbing systems. Today, STM boasts the most extensive experience on sodium sorbent milling systems for gas cleaning applications worldwide. It is one of only a handful of mill suppliers that are certified by Solvay for the supply of mills to be used with their processes.

As a result of our extensive experience, we have designed innovative machines that, thanks to the perfect integration of heavy-duty mechanical and advanced electronics, we are the only supplier that brings a wholly integrated milling solution, able to guarantee predictable performance, reliable production and energy efficiency - PLUS AN 8400 HOUR CONTINUOUS OPERATION GUARANTEE!

The Smart Mill - Systems Supplier + Equipment Designer

STM EcoSystems is one of the leading dry injection equipment suppliers with respect to R&D, engineering, design and manufacture of dry milling equipment. We are the first and only company in the world to offer a Smart Milling System, the Bicarmill.

What Do You Ask Of Your

Dry Sorbent Milling Equipment?

First of All, Maximum Efficiency and Reliability.

These characteristics are influenced by completely different factors: during the operating life of a mill, energy costs exceed capital investment by far, therefore an efficient employment of the energy seems to be of fundamental importance.

Only a system that provides maximum reliability can guarantee availability and continuity. Reliability, in this case, means continuous production of a milled product that meets a specific quality standard – and this reliability presupposes a system that provides maximum efficiency under all operating conditions.

More Results,

Lower Energy Consumption

STM EcoSystems Smart Mills resolve customer demands for:

Low energy consumption

Cool operation

Low sound emissions

Negative pressure operation

Minimal maintenance

Elevated reliability

Consistent product quality

Continuous production of milled product

Guaranteed particle size distribution

In order to achieve these objectives, many innovative solutions in the operational, access and maintenance systems have been developed.

The result are the STM EcoSystems Smart Mills, exceptional and reliable products, whose design is the product of all of our experience, with the quality and performance our customers have come to expect of the STM label.

For non pollution control applications, please visit the STM Micron website - click here

Bicarmill™ Smart Mill System

Bicarmill Smart Mill Installation Examples

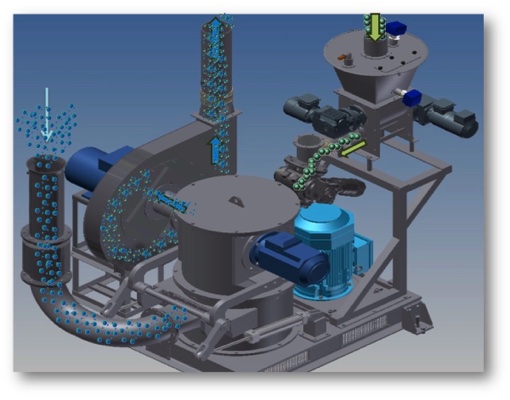

Compact Mill Schematic

Compact Mill

Easy Box Enclosed Milling System Containing Compact Mill and MDS Doser

JCF Hammermill Schematic and Typical Arrangements

STM EcoSystems - 83 Princeton Ave. Unit 3D - Hopewell - NJ - USA - 609.644.3797